Ordinary asynchronous motors are often unsuitable for inverter-driven applications due to their inability to handle variable frequency, voltage spikes, and thermal stress. To ensure long-term reliability, industrial users should select asynchronous inverter motors designed for inverter duty. By partnering with experienced asynchronous motor manufacturers, companies can benefit from motors with enhanced insulation, improved cooling, optimized rotor and stator design, and integrated protection features. This approach ensures consistent performance, longer motor lifespan, and efficient operation across a variety of industrial applications.

1. Design Differences Between Ordinary and Inverter Motors

Voltage and Frequency Adaptability

Ordinary motors are engineered to operate at fixed voltages and frequencies. When an inverter modifies frequency and voltage to control speed, the motor experiences electrical stresses it was not designed for, potentially damaging insulation and windings.

Insulation Class

Inverter-rated motors use higher-grade insulation materials capable of withstanding repetitive voltage spikes. Standard motors may not endure these conditions, resulting in partial discharges, hot spots, or breakdown.

Rotor and Stator Construction

Inverter motors often feature rotor bars and stator windings optimized to reduce eddy current losses and minimize overheating under variable frequency operation. Ordinary motors lack these optimizations.

2. Common Failures in Ordinary Motors Used with Inverters

Overheating: Variable frequency operation increases I²R losses in windings. Without enhanced cooling, temperatures rise rapidly.

Insulation Breakdown: High-frequency voltage spikes erode insulation material over time.

Vibration and Noise: Variable speed may induce mechanical resonance, particularly in motors not designed for inverter duty.

Reduced Lifespan: Accumulated stress shortens motor life, result in frequent maintenance or replacement.

3. Why Inverter Motors Are Better Suited

High-Grade Insulation: Inverter-rated asynchronous motors employ insulation systems that resist high-voltage spikes and thermal stress.

Improved Cooling Systems: Optimized fan design and housing ventilation ensure adequate cooling at all operating speeds.

Optimized Winding and Rotor Design: Reduces electrical losses, heat generation, and vibration under variable speed operation.

Protection Features: Built-in temperature sensors and compatibility with inverter protection functions help prevent motor failure.

4. Practical Recommendations for Industrial Users

To avoid problems when integrating motors with inverters, users should consider the following:

Motor Selection: Verify that the motor is inverter-rated and compatible with the intended voltage and frequency range.

Proper Installation: Ensure correct cabling, grounding, and shielding to reduce electrical noise and voltage spikes.

Regular Monitoring: Check temperature, vibration, and insulation resistance periodically to detect early signs of stress.

Manufacturer Consultation: Working with experienced asynchronous motor manufacturers like Zhejiang Ligong Motor Co., Ltd. ensures selection of motors specifically designed for inverter use.

5. Industrial Benefits of Using Inverter-Rated Motors

Choosing asynchronous inverter motors over ordinary motors brings significant advantages:

Operational Reliability: Reduced risk of unexpected downtime due to insulation or thermal failure.

Energy Efficiency: Motors maintain efficiency under variable load and speed conditions.

Lower Maintenance Costs: High-grade insulation and optimized design reduce repair and replacement frequency.

Extended Application Range: Suitable for machinery, textile production, food processing, printing, construction materials, and metallurgical industries.

Performance Stability: Motors sustain low vibration, low noise, and consistent torque, even under varying speed and load conditions.

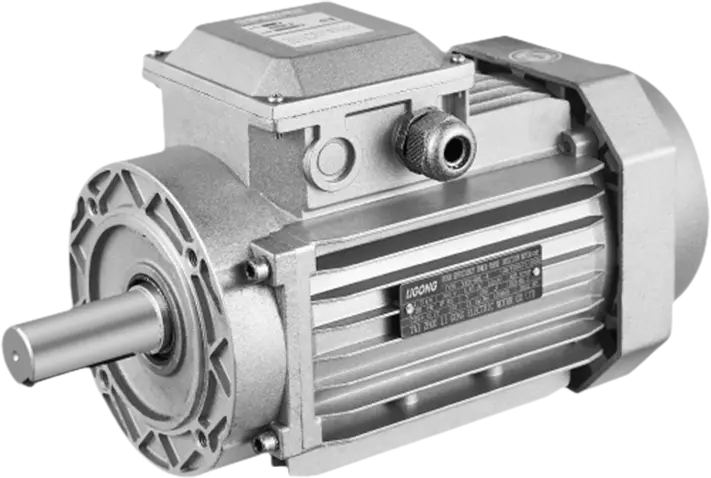

Ordinary asynchronous motors are built for constant speed operation with stable voltage and frequency, while inverter applications introduce variable frequencies, high dv/dt voltage spikes, and fluctuating currents. At Zhejiang Ligong Motor Co., Ltd., we specialize in designing inverter-compatible motors that address these challenges, providing reliable performance for modern industrial applications.

English

English 中文简体

中文简体 عربى

عربى