Energy efficiency has become a critical focus for manufacturers worldwide. As energy costs continue to rise, industrial operations are looking for innovative ways to optimize energy use without sacrificing performance. Energy Saving Motors are designed to provide just that, delivering high efficiency while consuming less power. These motors are particularly beneficial for continuous operations, such as in textile factories, food processing plants, and even metallurgy.

Frequency Conversion Motor, on the other hand, complement Energy Saving Motor by offering variable speed control. This capability enables companies to adjust motor speed based on operational needs, avoiding the energy waste associated with traditional fixed-speed motors.

The Benefits of Energy Saving Motors

Reduced Energy Consumption

One of the more significant advantages of Energy Saving Motors is their ability to lower electricity bills. These motors use less energy while maintaining the same power output, resulting in substantial savings over time.

Lower Environmental Impact

By consuming less energy, Energy Saving Motors help reduce the carbon footprint of industrial operations. This aligns with the growing global push toward sustainability, making energy-efficient motors an outstanding choice for companies that want to meet environmental regulations and improve their eco-friendly image.

Cost Savings

While the initial cost of Energy Saving Motors may be slightly higher, the long-term savings on energy bills and reduced maintenance costs make them a wise investment. These motors often require less maintenance due to their efficient design, causing to fewer repairs and longer operational lifespans.

How Frequency Conversion Motors Improve Efficiency

Optimized Power Usage

Unlike traditional motors that run at full speed regardless of the application’s requirements, Frequency Conversion Motors can adjust their speed to suit the task at hand. This means they only use as much power as is necessary, significantly reducing wasted energy.

Flexible Performance

These motors are ideal for applications that require variable speeds, such as conveyor belts, pumps, and ventilation systems. By adjusting the motor speed based on real-time needs, businesses can maintain consistent performance while saving energy.

Reduced Wear and Tear

Because Frequency Conversion Motors operate at lower speeds when full power is not required, they experience less wear and tear over time. This leads to lower maintenance costs and fewer breakdowns, further contributing to cost savings.

Case Study: How Energy Saving Motors and Frequency Conversion Motors Can Benefit Your Business

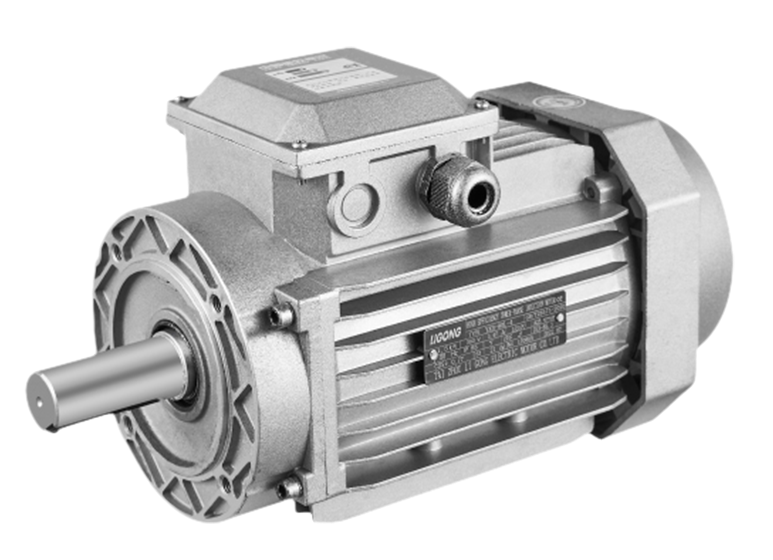

At Ligong Motor, our Energy Saving Motors and Frequency Conversion Motors have been successfully implemented in a variety of industries. One of our clients in the textile industry reported a 25% reduction in energy consumption after upgrading to our energy-efficient motors. This change not only lowered their operational costs but also improved the overall productivity of their machinery.

As industries continue to face pressures to reduce costs and minimize their environmental impact, the adoption of Energy Saving Motors and Frequency Conversion Motors is becoming increasingly important. At Zhejiang Ligong Motor Co., Ltd., we are committed to providing high-quality, energy-efficient motor solutions that deliver both performance and savings. By choosing our motors, businesses can achieve greater energy efficiency, lower operational costs, and contribute to a more sustainable future.

Ready to take your industrial operations to the next level? Contact us today to learn more about our Energy Saving Motors and Frequency Conversion Motors, and how they can help your business thrive.

English

English 中文简体

中文简体 عربى

عربى